Sheet Metal Fabrication Vs Off‑The‑Shelf Components: Why Custom Always Wins

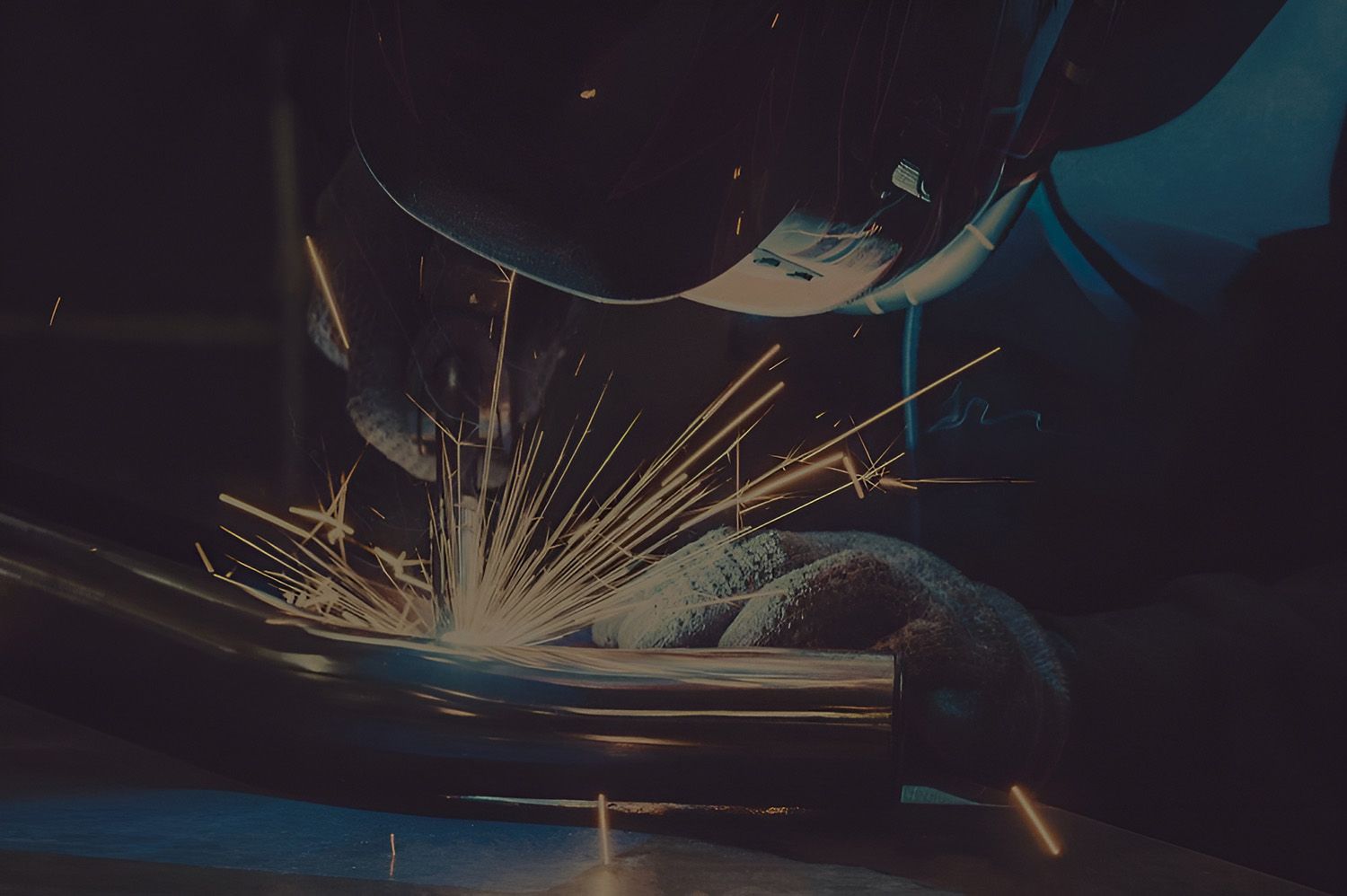

Imagine you’re working on a build or renovation where every detail matters — from fit to finish and durability. You order a generic part, hoping it will do the trick. But it arrives ill‑fitting, the material feels weak, and installation takes longer than expected. Now, picture a component designed specifically for your project: one that fits exactly, is fabricated from a material matched to its role, and is built to last. That’s the difference when you choose custom

sheet metal fabrication over off‑the‑shelf. Below, we’ll walk you through eight reasons why

custom fabrication wins—not just for big industrial projects, but also for builders, designers, engineers and homeowners who want reliability, control and value.

When Every Millimetre Matters: Precision Fit That Off‑the‑Shelf Can’t Match

Custom sheet metal fabrication provides parts made to your exact dimensions, which makes a significant difference when alignment, aesthetics, or structural load are involved.

- A bespoke bracket, enclosure or panel is cut, bent and finished to fit the space it’s going into—no guesswork or modification on‑site.

- You avoid having to force something into place, shim it up, or compromise the design because the “close enough” part doesn’t quite work.

- The result is a cleaner installation, stronger connections and better integration with adjoining elements.

- Generations of fabrication techniques now support very tight tolerances, which off‑the‑shelf items often can’t match.

Why Custom Metal Means Custom Strength

It’s not just about shape. Custom fabrication allows you to select the ideal material and thickness for the job, rather than relying on one-size-fits-all solutions.

Stainless steel, Aluminium, Mild steel

- Stainless steel is ideal for resisting corrosion in harsh environments or high-moisture settings.

- Aluminium offers lightweight strength and is ideal for applications where weight or handling is a concern.

- Mild steel can provide solid structural performance at a lower cost, provided the environment is suitable.

Off‑the‑shelf components are often made with the cheapest acceptable material rather than the best material for your specific scenario. When you go custom, you specify metal grade, finish and durability.

Stock Doesn’t Solve Design Problems—Custom Fabrication Does

Standard components often limit you to fixed shapes, sizes and functions. Custom sheet metal fabrication on the Gold Coast breaks those limits.

- Create unique shapes to match architectural design, mechanical constraints or aesthetic ambitions.

- Add special cut‑outs, channels, brackets, integration features or bespoke profiles that wouldn’t exist in a catalogue.

- Finish options (powder coating, galvanising, and anodising) can be aligned with interior design, branding or outdoor durability.

This gives you real design freedom—not just “one of these will do” but “this is exactly what we need”.

Reducing Project Delays With Made‑to‑Order Metal

Waiting for a standard part that’s out of stock or doesn’t quite fit can slow down a project. Custom fabrication often streamlines the schedule.

- When you commission the part specifically, you avoid searching for something off-the-shelf that might need modification.

- Fabricators often work with you from design through delivery, so changes, tweaks, or revisions can occur within the same workflow.

- Fewer on‑site adjustments, less stopping and re‑ordering means smoother progress and fewer surprises.

For builders and installers, such timing reliability is crucial when coordinating trades and completing finishing touches.

Built to Last: How Fabricated Components Outperform Stock Over Time

Durability and lifecycle matter to homeowners, engineers and designers alike. Custom parts often outlast generic ones.

| Feature | Custom Fabricated Components | Off‑the‑Shelf Components |

|---|---|---|

| Material matched for use | Yes (specified grade, finish) | Often generic grade, limited options |

| Fit and finish | Precisely made and installed | May require adjustment or compromise |

| Maintenance & wear‑resistance | High when designed correctly | May show fatigue or corrosion earlier |

| Replacement frequency | Lower due to tailored design | Higher if the part doesn’t suit the environment |

When you tailor fabrication to the environment and load conditions, you get longer‑term value—rather than replacing or retrofitting sooner.

The Cost Myth: Why Custom Metal Often Saves Money

At a glance, off‑the‑shelf seems cheaper. However, when you factor in real costs—such as installation time, modifications, failures, and replacements—the custom route often proves more cost-effective.

- Reduced waste and re‑work thanks to precise fit and correct material.

- Fewer installation issues, which means less time spent modifying or adapting on site.

- Longer lifecycle and better performance mean fewer future adjustments or replacements.

In many projects, choosing custom fabrication pays back through reduced hassle and better outcomes—even if the initial cost is slightly higher.

Tailored Fabrication for Complex or Constrained Spaces

Projects with awkward geometry, retrofit scenarios or complicated layouts require more than standard components can deliver. Custom sheet metal fabrication shines here.

- In tight or awkward spaces, a component can be fabricated to the exact shape required—no “fitting in” or cutting around existing elements.

- For retrofits or upgrades, custom parts can be integrated with the existing structure, services, or architecture, rather than forcing a mismatch.

- For specific design aesthetics or finishing touches, you get the creativity that stock parts simply don’t offer.

This means builders, designers and engineers aren’t forced into compromise because the only available part is “close enough”.

Working Directly With Fabricators Means Total Project Control

When you use a custom fabrication service, you gain control over design, materials, delivery and installation. That kind of collaboration often isn’t possible with off‑the‑shelf.

- You can work with the fabricator early to align the part with other trades, services and finishing elements.

- Changes can be made in real time—if a dimension changes or a new constraint appears, you’re not locked into a catalogue part.

- Documentation, quality control, and traceability of material and processes all become part of the workflow, which suits designers and engineers looking for accountability.

This collaborative approach means fewer surprises, better integration with the rest of the project and stronger alignment with the overall build strategy.

Let’s Make It Fit — Not Force It

At Sheetmetal Improvements & Design, we work with builders, designers, engineers, and homeowners to deliver made‑to‑order metal components that do more than just "get the job done"—they do it right. Whether you’re dealing with tricky spaces, custom design briefs, or performance requirements that off‑the‑shelf parts can’t meet, we can fabricate to suit.

If you're ready to take control of the design, durability and finish of your project components,

get in touch via our contact page or

give us a call. Let’s discuss your plans and explore how we can bring your specifications to life with precision, efficiency, and local expertise.